Parts & Services

-

Gearbox Bearings

Upgraded gearbox bearings in stock for over 40 gearbox models.

-

Blade Bearings

Upgraded blade (pitch) bearings in stock for many platforms. Solutions for the toughest failure modes such as; ellipse truncation, raceway failure, and even ring cracking.

-

Main Shaft Bearings

Upgrades with DLC on the rollers, special materials, and cage designs.

-

Pitch Motor Renewal

Reusing failed motors and rebuilding with upgraded components our Pitch Motor Renewal Program is the green way to improve the life of your pitch motors.

-

Generator Bearings

Insulated coating or ceramic hybrid bearing options in stock for many wind turbine generators.

-

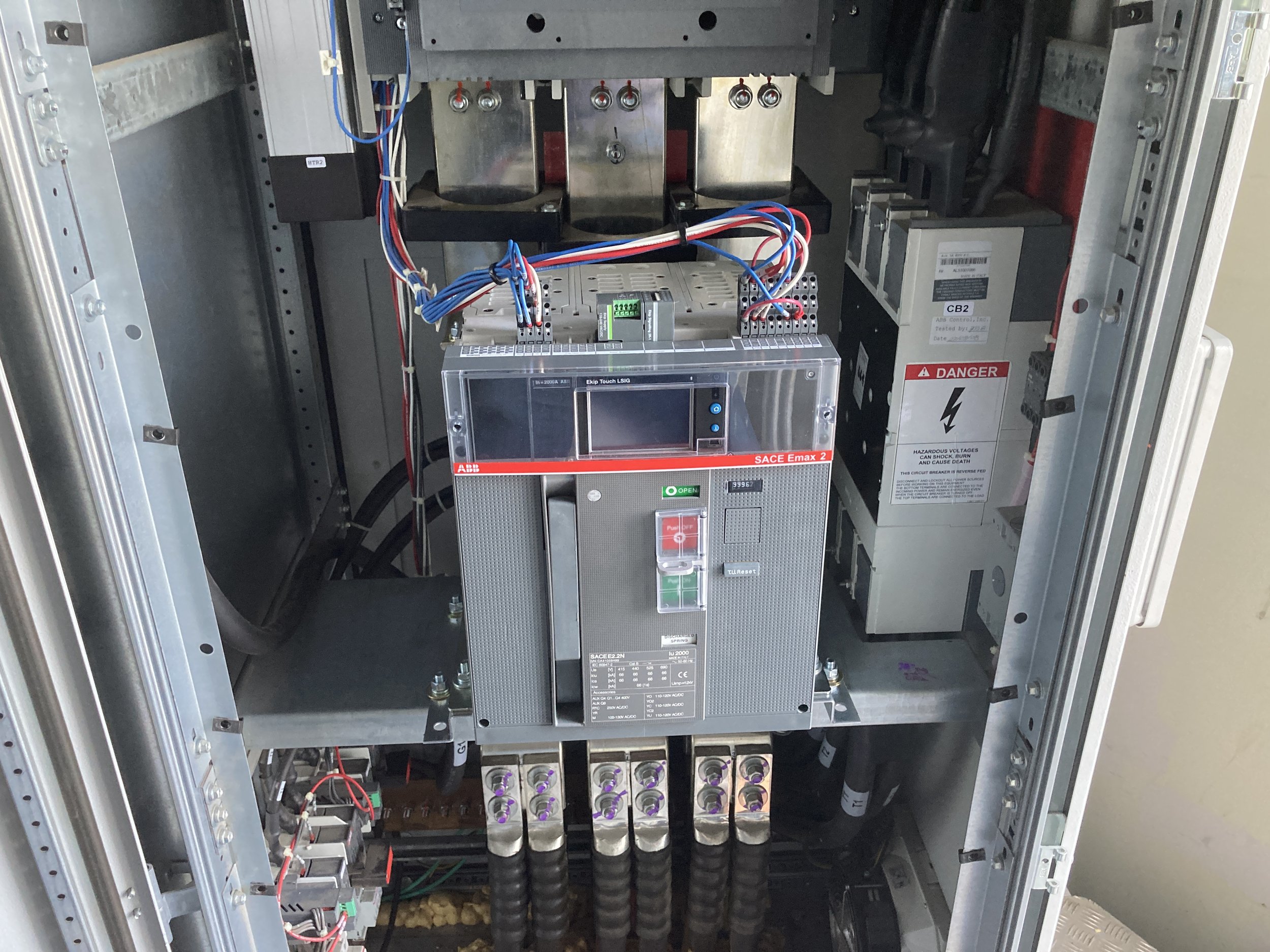

CB1 Retrofit

Our CB1 retrofit for GE 1.5 turbines includes everything needed to make essentially a drop in replacement.

Working with the top manufacturers in the business.

As the leading supplier of wind power transmission products, we only work with the best in the business.